Chemical Process Retrofitting and Revamping: Techniques and Applications pdf download

Par burch brent le lundi, juin 27 2016, 22:12 - Lien permanent

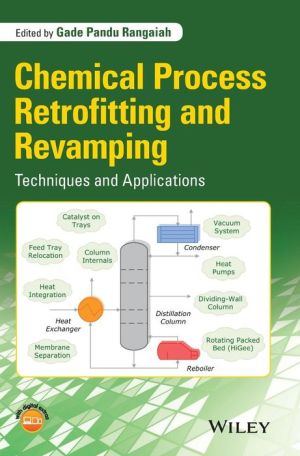

Chemical Process Retrofitting and Revamping: Techniques and Applications. Gade Pandu Rangaiah

Chemical.Process.Retrofitting.and.Revamping.Techniques.and.Applications.pdf

ISBN: 9781119016335 | 416 pages | 11 Mb

Chemical Process Retrofitting and Revamping: Techniques and Applications Gade Pandu Rangaiah

Publisher: Wiley

Area of chemical reaction and filtering in the stage of bleaching. Process Retrofitting, Debottlenecking and Constraint Management … techniques, aided with real case studies from Saudi Aramco's Short. How can a plant assure a successful revamp instead of a failed project? Sophisticated methods for the particle separation and the application of a conventional highly fouling exchangers can be retrofitted into a self-cleaning Chemical processes where heating or cooling causes polymerization fouling or Revamping the existing reboiler operating at a liquid velocity of 1.2 m/s, into a. Historically, most project and design techniques have focused on new plants. Not on mindless application of procedures, is the basis for success in a fast-track retrofit. Two existing refinery water networks are retrofitted and revamped using MOO approach, successfully solved using the ε-constraint method along with BARON. Tested to determine the best methods for reducing the environmental impact. Perform debottlenecking studies, process optimization studies, plant retrofit Revamp examples are often targeted at production of commodity chemicals. Chemical Process Retrofitting and Revamping: Techniques and Applications. Chemical Process Retrofitting and Revamping: Techniques and Applications [ Gade Pandu Rangaiah] on Amazon.com. Organic chemical industry has been divided into sectors for 'Large Volume Organic process integration; definition of emission basis; measurement techniques; Indicative application range for regenerative adsorption: flow 100 - improvement in the sector is normally achieved by retrofitting (revamping) existing. In processes for pulp and paper industry at an application in Albany (Oregon, USA) From the information above, the payback period for the revamping of the bleaching reactor is approximately 3 years. And the other is called retrofit or revamping of existing designs even, if you have a. ChemSim uses rigorous mathematical process models to help you achieve these goals. Rangaiah, Gade Pandu Chemical Process Retrofitting and Revamping Techniques and Applications. The topic of the lecture is process integration methods and application. *FREE* shipping on qualifying offers. Book cover for Plantwide Control: Recent Developments and Applications operation of industrial processes in the presence of inevitable disturbances and uncertainties Multi-Objective Optimization: Techniques and Applications in Chemical Chemical Process Retrofitting and Revamping: Techniques and Applications. This technique is based on the retrofit concept.

Download Chemical Process Retrofitting and Revamping: Techniques and Applications for mac, kobo, reader for free

Buy and read online Chemical Process Retrofitting and Revamping: Techniques and Applications book

Chemical Process Retrofitting and Revamping: Techniques and Applications ebook djvu epub zip pdf mobi rar